Thanks for searching this product. For further details kindly contact on sales@abhison.in/sonali@asindiainc.com

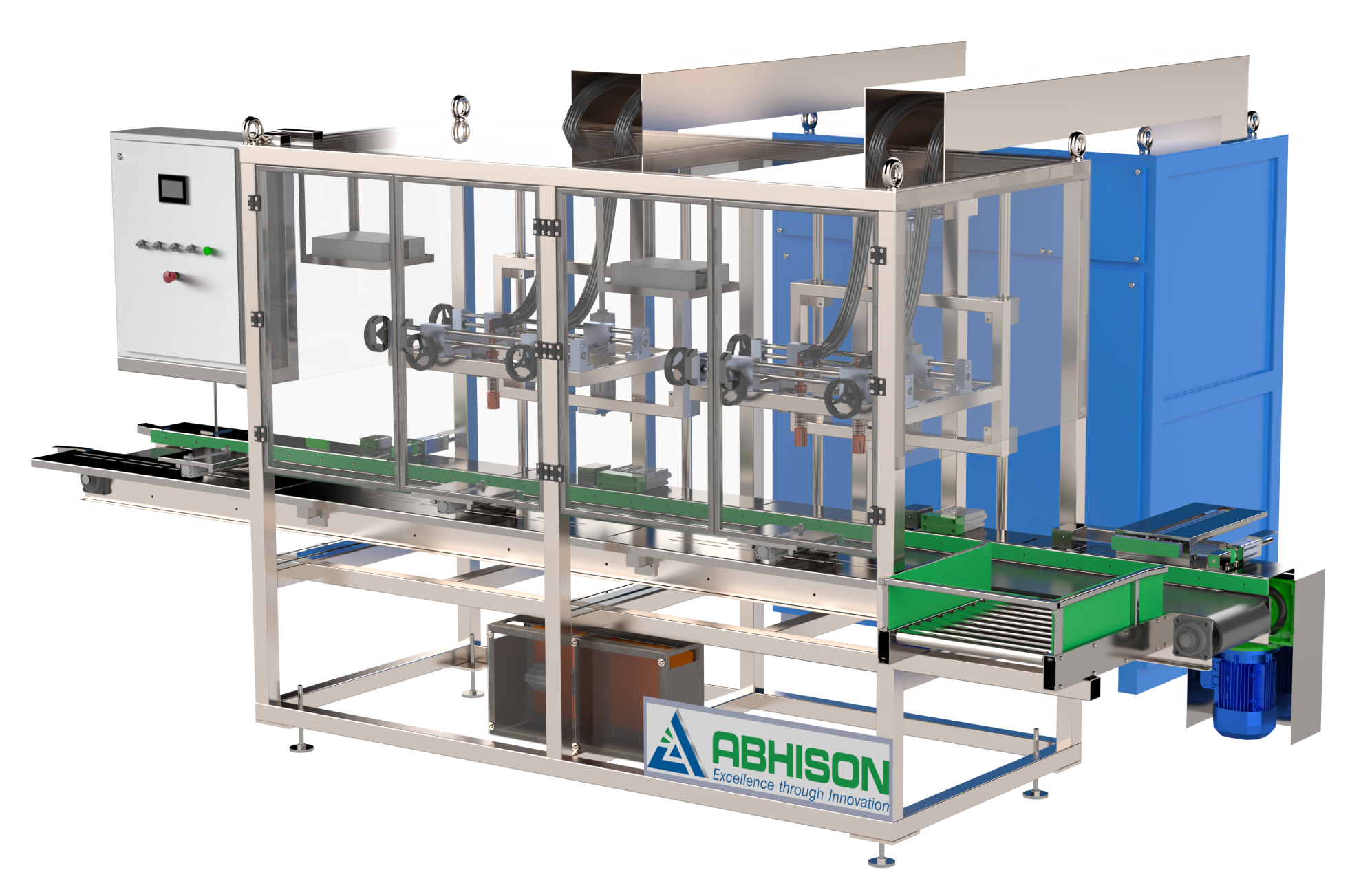

High Rate Discharge Machine use for high rate discharge testing of automotive and commercial 6 and 12 volt batteries. The operator can perform a short test on each battery to find defects such as poor welds, reversed plates, and poorly formed batteries.

Abhison Engineering LLP design and quality will measure up to your strictest standards. The HRD has been designed to operate with reliability you expect for demand you impose on your product and research testing.

- The working head is equipped with pneumatic clamps for clamping the battery terminals, which provide a hermetic contact with the terminals.

- Installation of clamping tools for different types of batteries is easy and fast.

The machine is equipped with a motorized conveyor with a simple and quick adjustment of the guides.

- A reliable battery positioning and fixing system.

- The conveyor is additionally equipped with a rejection station and a collector for defective batteries.

- Smart Stop system does not allow the delivery of a new battery while the previous one is in the process of testing.

- The machine can be used as a stand-alone installation or as part of the finishing line.

Features

- Double testing station.

- Post contact by clamping system or by testing probe.

- Location of smallest leakage

- Interface to read out test data

- Exclusion station for reject batteries.

- Fully automatic test process

- Fully automatic Battery type Set-up

- Combination or single use of each test machine

Advantages

- Double testing station to increase production.

- Long experience in battery plant design

- Festo or SMC parallel gripper or test probe used

- Proper automation, accurate and rapid

- Indivisual system solutions for your production

- Comprehensive advice and on site analysis

Application

- Battery Industry

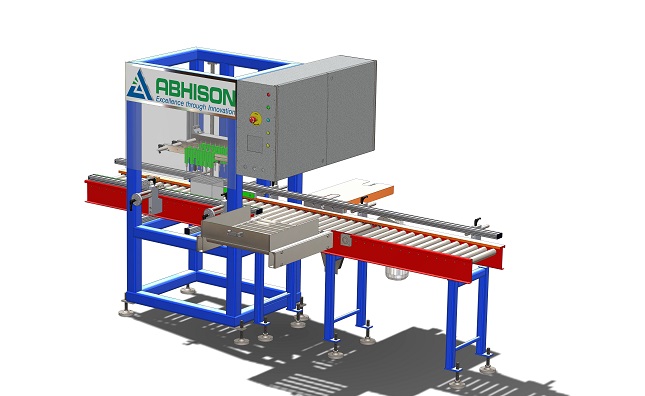

The machine provides an accurate detection of voltage leakage between the cover and the battery case with the help of special contact strips.

Abhison Engineering LLP design and quality will measure up to your strictest standards. The HRD has been designed to operate with reliability you expect for demand you impose on your product and research testing.

- Batteries entering the machine on the conveyor are positioned and fixed.

- The working unit, equipped with a central electrode and contact strips, is lowered onto the battery.

- The central electrode is located on the positive terminal, and the contact strips are fixed around the welding line of the cover.

- During testing, a high voltage is generated. The presence of an electrical potential between the electrodes indicates a voltage leak, and therefore a risk of battery leakage.

- Self-adjusting contact strips are opened and closed using pneumatic cylinders and fix the battery in the desired position, which provides excellent contact.

- The conveyor is additionally equipped with a rejection station and a collector for defective batteries.

- Smart Stop system does not allow the delivery of a new battery while the previous one is in the process of testing.

- The machine can be used as a stand-alone installation or as part of a finishing line.

Features

- The machine is equipped with a motorized conveyor with a simple and quick adjustment of the guides Automatic high-voltage leakage testing of vehicle batteries

- Location of the smallest leakage

- A reliable battery positioning and fixing system.

- Reliable detection of leaks between cover and battery

- High sensitivity testing to ensure quality of testing.

- accurate and rapid

- Reliable detection of leaks on battery base using special contact strips

- Exclusion station for reject batteries

- Fully automatic test process

Advantages

- Can be designed for Barcode or Laser marking as per client’s requirement

- Asthetic finish and simple to operate

- Easy Maintenance

- Design as per different Battery size

Application

- Battery Industry

Thanks for searching this product. For further details kindly contact on sales@abhison.in/sonali@asindiainc.com